Offshore & Engineering

PVD 5 Underwater Inspection in-Lieu of Dry-docking

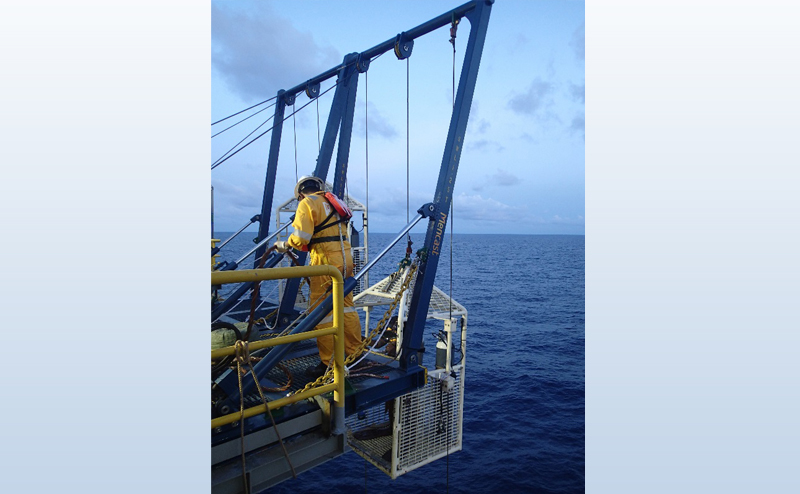

A special breed of men departed to Vietnam at the beginning of summer in 2014 to accomplish not many would experience. Mencast Subsea was contracted to commence and complete an inspection off Vung Tau, Vietnam.

These inspections (UWILD) of MOPU (Mobile Offshore Production Units) takes place every 2.5 years. The reason for this being done is to allow the vessel to continue working at location without disrupting operations and heading to a dock.

At Mencast we understand that every moment is valuable in the world of energy, with our responsiveness and speed we are able to mobilize our men synced with Superior Technical Ability to be Fully Engaged on the task at hand not forgetting Environmental Championship with the highest safety standards. Dependability together with a strong Corporate Ethos encompasses the mindset of team led by Max Irrawan our dive Superintendent.

The afternoon before a full night/day of operations, the team will discuss and align the objectives for the following days. The plan is to run 24hrs operations on a 12hour shift rotation to maximize the effective dive times planed.

During the day when the visibility is much better, we are able to take a couple of shots of what we do. These are some pictures of the cleaning process prior to the inspection which will be done on the final day.

In the end, we were able to complete the intensive cleaning and thorough inspection within the expected proposed schedule and achieve the expected result despite the challenges faced with the weather and swells.

Mencast Subsea is either at height or we go to great depths to accomplish challenging projects. These men and ladies certainly do not like being grounded. Having expertise in Rope Access Solutions and Diving Operations including being members of IMCA, IRATA along with being accredited by various OGP Companies like Shell, ExxonMobil and BP, we are able to deploy our teams anywhere, anytime.

Mencast Subsea capabilities include,

- All Class approved Underwater NDT inspections, Installation of various underwater modules, Certified Underwater Welding/Cutting.

- Topside NDT, DROPS survey and LEEA accreditations.

- All done with utmost consideration to the highest safety standards.